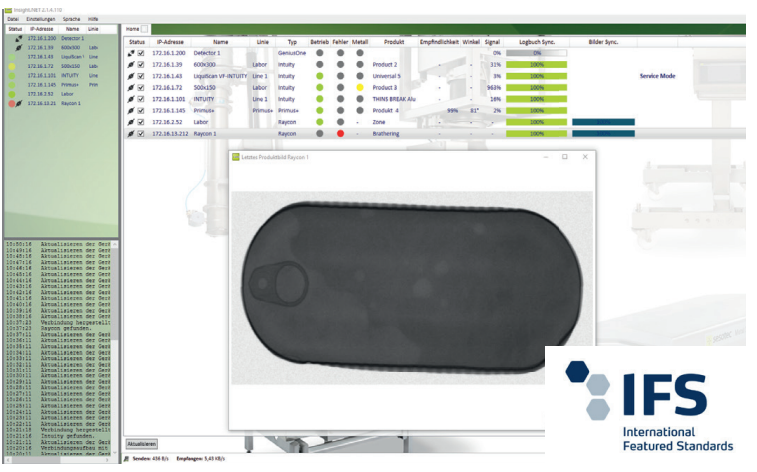

Metal Detection Food » X-ray Inspection System » Raycon D+ MX

RAYCON D+ MX (Intelligent X-ray inspection system for packaged products)

- Conformity & Accuracy: The RAYCON D+ MX offers detection accuracy from 0.6 mm, better than the IFS requirement.

- Safety for people & product: The legal limit of 1 mSv/a is clearly undercut at every point.

- Simple operating concept: Thanks to the Auto-Learn function, no specific prior knowledge is required.

- Sophisticated hygiene concept: Open, modular design as well as tool-free access to the conveyor area for easy cleaning.

- Efficiency in all areas: High belt speeds and multi-lane inspection on up to four parallel lines.

- Reliable and fast service: Lifetime warranty package and remote service via Teamviewer / Pilot app, among others.

The new RAYCON D+ MX

Our X-ray systems have been specially developed for use in the food industry and reliably detect foreign bodies such as metals, as well as glass, ceramics, stones, raw bones, PVC and many other product defects. Through this precise inspection, conformity with all important guidelines of the food industry such as IFS, BRC or FSSC 22000 is fulfilled and reliable protection against complaints and recalls can be ensured.

The Sesotec 6-point concept for optimal X-ray inspection

One system, numerous advantages :

Conformity & Accuracy

Reliable detection of metallic and non-metallic foreign objects throughout the inspection area enables compliance with all current specifications and standards.

Safety for people & product

Thanks to highly effective radiation protection and dosed use of X-rays, the RAYCON D+ MX enables all-round safe operation for people and products.

Simple operating concept

Thanks to a large touchscreen, easy-to-understand user guidance and features such as the Auto-Learn function, the RAYCON D+ MX offers particularly easy handling in everyday use.

Sophisticated hygiene concept

The open, modular design and the possibility of access to the conveyor area without tools simplifies cleaning and maintenance.

Efficiency in all areas

Thanks to high speeds and multi-lane capability, up to 300 products per minute can be inspected in real time – on a maximum of four parallel lines.

Reliable and fast service

With warranty services, a combined on-site and remote service, and targeted training, you have optimal support for smooth operation.

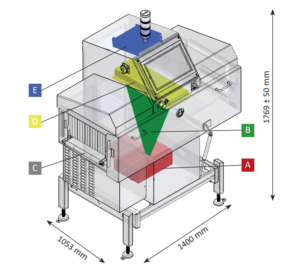

The system comprises of the following main components:

(A) X-ray tube

Here the X-rays are generated electrically. It exits the tube through a narrow slit and penetrates the product to be examined from the back to the front as a fan-shaped beam.

(B) X-ray beam

(C) Transport system

A PE flat belt (self-guiding) transports the product to be examined evenly through the X-ray beam. This makes it possible to scan the product line by line.

(D) Detector unit(0.4 mm and 0.8 mm resolution)

The linear detector installed above the inspection aperture converts the incoming X-ray beams into an electrical signal from which a digital X-ray image is generated.

(E) Industry-type PC

This is where image evaluation and precise control of the reject systems

take place.

The detectability of foreign bodies in X-ray systems with single-energy technology depends primarily on the density of the foreign body. All foreign bodies with a density significantly higher than the product density are very well detectable. These include, for example, metals, glass, stones, ceramics in products such as sausage, cheese, meat, etc. However, thanks to the high-resolution detector and the sophisticated software evaluation using a large number of filters in the RAYCON D+ MX, bones, rubber, Teflon, PVC, etc. can also be reliably detected. A free test with your product provides you with a meaningful basis for decision-making.