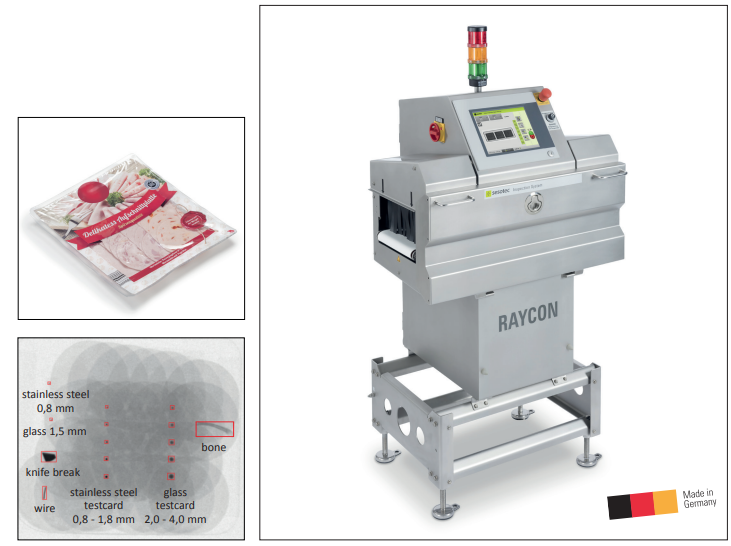

RAYCON EX1 (Product inspection system for slim and packaged products at moderate pricing)

The system comprises the following main components:

(A) X-ray tube

This is where X-rays are electrically generated. The X-rays are emitted from the tube through a narrow slot and as a fan-shaped beam pass through the product to be inspected from back to front. Depending on the product height and density a part of the X-rays is absorbed by the product.

(B) X-ray beam

(C) Transport system

A PE flat belt (self guiding) uniformly transports the product to be inspected through the X-ray beam, which makes it possible to scan the product line-by-line.

(D) Detector unit

The linear detector line that is installed beside the conveyor belt converts the arriving X-rays into an electrical signal from which a

digital X-ray image is created.

(E) Industry-type PC

The PC is used to evaluate the images and to accurately control the reject systems.

The system comprises the following main components:

(A) X-ray tube

This is where X-rays are electrically generated. The X-rays are emitted from the tube through a narrow slot and as a fan-shaped beam pass through the product to be inspected from back to front. Depending on the product height and density a part of the X-rays is absorbed by the product.

(B) X-ray beam

(C) Transport system

A PE flat belt (self guiding) uniformly transports the product to be inspected through the X-ray beam, which makes it possible to scan the product line-by-line.

(D) Detector unit

The linear detector line that is installed beside the conveyor belt converts the arriving X-rays into an electrical signal from which a digital X-ray image is created.

(E) Industry-type PC

The PC is used to evaluate the images and to accurately control the reject systems.

Detectability of different materials depending on their density

The RAYCON EX1 product inspection system is characterised by the following performance features:

- Inspection area: 220/120 (W x H)

- Throughput: ~220 pcs./min. (product specific)

- Detection capability starting from Ø 0,6 mm

- 60W Low-Energy X-Ray generator

- Highest operator safety due to low X-Ray emission < 0.5µSv/h

- Total length of 800mm only

- Modular and stable frame design allows easy transportation and safe installation

- Ambient temperatures from 0°C to +40°C

- IP 54 protection class

- Reject system: signal only (for customer specific reject systems)

Evaluation software

The product inspection system is equipped with a high-performance industry-type PC with real-time operating system and sophisticated

visualisation software.

The system is operated by way of a 10“ – LCD monitor with touch-screen.

X-ray images are evaluated by means of a product-specific visualisation software. Contaminated or defective products are detected and separated.

User Interface

Drag & Drop menus

The operator receives a visual feedback instantly

– Time saving

Menu guide

The operator is guided by the software through necessary steps of product setup or troubleshooting

– Time saving

Easiest and fastest product setup

Autolearn with 5 product samples only

– Startup in less than 2 minutes

Retrain for automatic sensitivity adjustment.

Software increases/decreases sensitivity automatically due to operators

command by just marking the x-ray image with fingers

– Saves time consuming adjustments

No special knowledge required

RAYCON EX1 design overview

Design & Hygiene:

Saving time for maintenance & cleaning due to:

– Inclined surfaces, water flows off easily

– Tool-less accessibility

– Tool-less removal of curtains in less than 1 minute

– Tool-less conveyor belt removal within 2 minutes