Metal Detection Plastics » Metal detection systems for material columns(Plastics) » PROTECTOR PROFESSIONAL

PROTECTOR PROFESSIONAL (High-performance Metal separator for extruders, injection-moulding and blow-moulding machines)

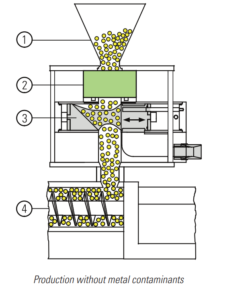

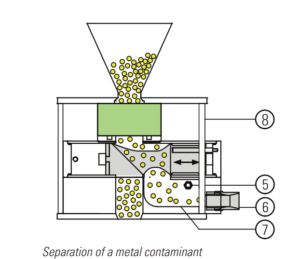

Frequently even smallest metal particles in the plastic melt are the cause of expensive malfunctions in injection moulding, extruding, and blow moulding. With the growing use of regranulate and regrind materials the proportion of such metal contaminations is further increasing. Choked nozzles, filters, and hot-runner systems frequently enough result in loss of production, downtimes, and delayed deliveries. The PROTECTOR PROFESSIONAL metal separator is installed directly above the material inlet of an injectionmoulding machine, extruder, or blow-moulding machine. It detects all magnetic and non-magnetic metal contaminants (steel, stainless steel, aluminium, …) – even if such contaminants are enclosed in the product. Metal contaminants are automatically and reliably separated by means of the reject unit (“Quick-Valve”).

The special design of the PROTECTOR PROFESSIONAL guarantees highest scanning sensitivity for smallest metal particles even under high mechanical loads, which may result from high superstructural assemblies, for example when various conveying, dosing, mixing, or feeding units are used simultaneously. The design with integrated reinforcing frame ensures that the high-performance detection unit is in no way affected by vertical mechanical forces.

- Material hopper

- Detection coil

- Separation unit

- Converting machine

- Metal contamination

- Venturi nozzle

- Reject outle

- Reinforcing framework

Metal separator with remote Control Unit PRIMUS+