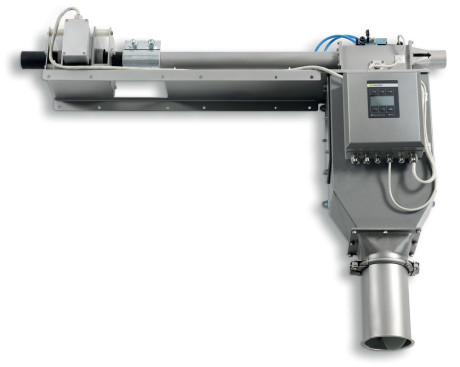

GF (Metal separator for pneumatic conveyor pipes)

- Detects and separates magnetic and nonmagnetic metal contamination, even when enclosed in product

- Reduces costly tool and machinery damage and prevents machinery downtimes

- Ensures product quality

- Prevents customer complaints

- Breaks even within a short period of time

- Highest sensitivity for all metals with high noise immunity against vibrations and electric smog

- Separates metallic contaminants without disrupting production flow or reducing conveying speed

- Shutter valve prevents leak air in pipeline

- Assembling frame guarantees quick and easy installation; mounting position (vertical, horizontal) selectable on site

- Stainless steel separation mechanics, junctions and separation flaps (1.4301)

- All units are pre-assembled for easy installation; Space-saving and compact design

- Minimal loss of good material through „Quick-Flap“separation unit

- Easy operation of the control unit through pre-set parameters

- Auto-Set (auto-teach function) or manual product compensation (no fixed setting) for improved adaptation to the intrinsic conductivity of the product to be inspected

Small metal particles in the plastic melting process often result in costly breakdowns of injection moulders, extruders and blow moulders. The quantity of such metal contaminants increases throughout the processing of regranulates and grinding stock. As a result, clogged nozzles, filters and hot channel systems can lead to production downtime and delayed delivery.

The metal separator GF is used in vacuum and pressure pipelines to protect injection moulders and converting machines.

It detects all magnetic and non-magnetic metal contaminants (steel, stainless steel, aluminium, etc.) – even when they are enclosed in the product. Metal contaminants are ejected via the “Quick-Flap” separation unit.

>

>

Installation example: Metal separator GF installed in a vertical

pipeline (old version)

- Detection coil

- Detection tube

- Separation unit

- Metal

- Collecting tray

- Shutter valve (used for vacuum pipelines)f

- Metal separator GF with detection- and separation unit

- Collecting tray for reject material

- Control Unit PRIMUS+

- Optical and audible signal

- Digital incident counter

- Air pressure monitoring

- Design for bulk material temperature of up to 140˚ C

- Adapter plate system

- Magnetic separator SAFEMAG

- UL/CSA Certificate

- Plastics industry

- Tool and machinery protection for extruders, injection moulders and blow moulders