Description

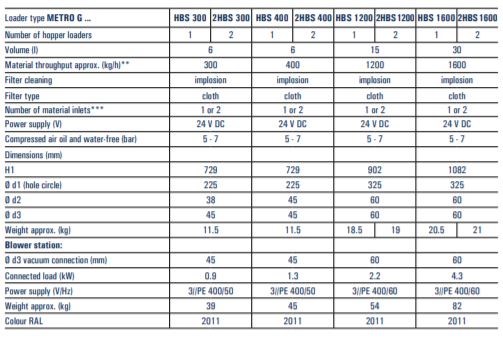

The METRO HBS three phase material loaders offer a wide choice of loader-blower sets and are designed for higher throughputs from 300 up to 1600 kg/h. The units are supplied with a separate three-phase floor standing blower station which is low-noise and maintenance-free. The control panel is located at a convenient height, eliminating the need to climb onto the processing machine. An alarm indicates insufficient material.

The METRO HBS models offer a wide choice of loader-blower sets

and are designed for higher throughputs from 300 up to 1600 kg/h.

The units are supplied with a separate three-phase floor standing

blower station which is low-noise and maintenance-free. The control

panel is located at a convenient height, eliminating the need to

climb onto the processing machine. An alarm indicates insufficient

material.

Highly efficient automatic implosive filter cleaning is standard on all

METRO HBS loaders.

METRO HBS with blower station

METRO HBS units are also available with two material inlets. A

separate mixing valve is not needed as the METRO HBS loader has

an integral proportioning function for virgin and regrind material. The

ratio between the materials is precisely adjustable, so that the

loader delivers a completely homogeneous mixture.

Up to two loaders plus a blower station can be controlled through a

single control panel. In effect, processors can set up a small

conveying system with METRO HBS loaders serving either two

machines or one machine and a drying bin.