RAPID 6000

Description

Metal Detector for Free-Fall Applications

The RAPID 6000 metal detector is used for the inspection of bulk materials in free-fall conveyor pipes. It detects all magnetic and non-magnetic metal contaminations (steel, stainless steel, aluminum, …) – even if such contaminations are embedded in the product. Metal contaminations are rejected by means of a swivel hopper. The RAPID 6000 metal detector primarily is used in industries with high hygienic demands. The chemical industry, pharmaceutical industry and food industry are the typical fields of application.

Description of The Metal Detector

• Metal detector for the inspection of coarse-grained, flaky, light, fibrous, crumbly, and moist bulk materials

• This metal detector can Detects magnetic and non-magnetic metal contaminations

• Separation by way of swivel hopper

• Hygienic design for easy cleaning metal detector

• This metal detector Complies with IFS and HACCP

• Separation unit and product-contacting metal parts completely made of stainless steel 1.4301 (AISI 304)

• Low mounting height guarantees easy integration of the metal detector in existing pipe systems

• This metal detector includes Separation unit with large cleaning opening

• Auto-learn function with product compensation included in this metal detector for optimal adaptation to the intrinsic conductivity of the product to be inspected

• Metal detector can Increased interference immunity to electromagnetic pollution and vibration

• Metal detector has Highest scanning sensitivity for all metals

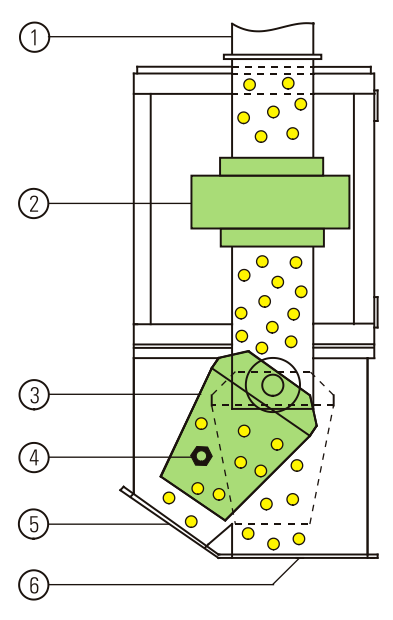

Function chart

- Inlet

- Detection coil

- Swivel hopper

- Metal contaminant

- Reject outlet

- Material outlet

Applications of The Metal Detector

• Incoming inspection (product purity and machine protection) of spices, ingredients, raw materials, etc. Prior to the processing machine (e.g., mill).

• Quality inspection (product purity) of herbs, tea, fibers, etc. Directly before filling in big bags and cartons.

• Quality inspection of breakfast cereals, noodles, chips, directly before a bag-forming, filling, and sealing machine.

GENIUS ONE Control Unit

• This metal detector included Highest sensitivity for all metals (2-channel technology)

• Digital signal processing and quartz-stable search frequency

• State-of-the-art microprocessor technology with self-monitoring, auto-balancing, and temperature compensation

• Product compensation with auto-learn function

• This metal detector has multi-product memory

• Password protection / access protection available in this metal detector

Advantages of The Metal Detector:

Versatile Application: this metal detector Suitable for a wide range of materials, making it versatile for various industries.

Comprehensive Metal Detection: Capable of detecting both magnetic and non-magnetic metal contaminants for a thorough inspection process.

Efficient Separation: The swivel hopper of the metal detector enhances the efficiency of the metal detection process.

Hygienic Design: this metal detector Easy cleaning facilitated by a hygienic design and the use of stainless steel 1.4301 (AISI 304) for product-contacting parts, crucial for industries with strict hygiene standards.

Compliance with Standards: metal detector Meets IFS and HACCP standards, ensuring adherence to internationally recognized criteria for food safety and quality management.

Corrosion Resistance: this metal detector Construction with stainless steel ensures corrosion resistance, contributing to the longevity of the equipment.

Easy Integration: Low mounting height allows for easy integration into existing pipe systems, this metal detector also providing flexibility for installation in various setups.

Convenient Maintenance: in this metal detector Design features, including a large cleaning opening in the separation unit, facilitate easy maintenance and cleaning processes.

Adaptive Technology: Auto-learn function with product compensation in this metal detector enables optimal adaptation to the intrinsic conductivity of the inspected product, enhancing accuracy.

Enhanced Immunity: this metal detector can Increased interference immunity to electromagnetic pollution and vibration contributes to stable and reliable performance in diverse operating environments.

High Sensitivity: The highest scanning sensitivity for all metals ensures detection of even small or subtle metal contaminants, also this metal detector enhancing the overall effectiveness of the inspection process.