Introduction

In the landscape of industrial chemicals, hexavalent chromium (Cr6+) holds a dual status. It is a valuable component used in a wide array of processes, from creating vibrant pigments and anti-corrosive coatings to chrome plating and stainless-steel production. However, alongside its utility lies a significant danger. Hexavalent chromium is recognized globally as a highly toxic and carcinogenic substance, posing serious risks to human health and the environment if not managed with extreme care. It is a restricted substance under the RoHS directive.

The Challenge:

The Hidden Danger in Industrial and Environmental Samples

Exposure to hexavalent chromium can lead to severe health consequences. Regulatory bodies have confirmed that inhaling airborne Cr6+ is a direct cause of lung, nasal, and sinus cancers. Further risks include damage to the liver and kidneys, as well as severe irritation to the respiratory tract and skin upon contact.

Given these dangers, the challenge for a multitude of industries—from manufacturing and metalworking to environmental monitoring—is clear. They must be able to accurately detect and quantify even trace amounts of Cr6+ in their products, wastewater, and local environment. Without a reliable, sensitive, and accessible testing method, companies risk non-compliance with safety regulations, potential harm to employees and the public, and damage to consumer trust.

The Solution:

Precise Quantification with UV-Vis Spectrophotometry

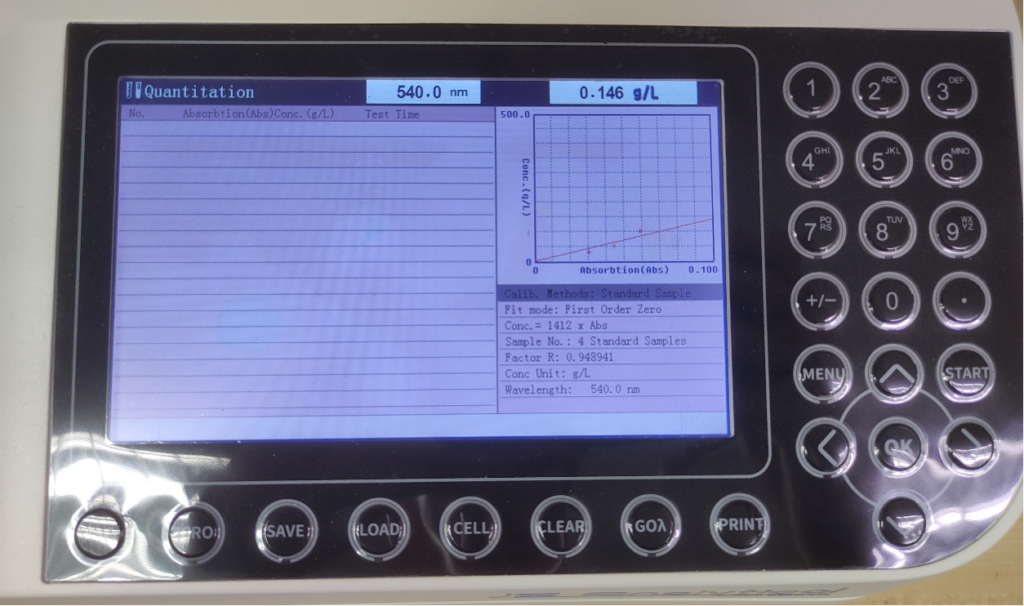

Addressing this critical need, UV-Vis (Ultraviolet-Visible) spectrophotometry stands out as a robust and highly effective analytical technique. UV-Vis spectrophotometers provide a straightforward and reliable way to measure the concentration of hexavalent chromium, turning a complex safety challenge into a manageable process.

The principle behind the method is elegant and precise:

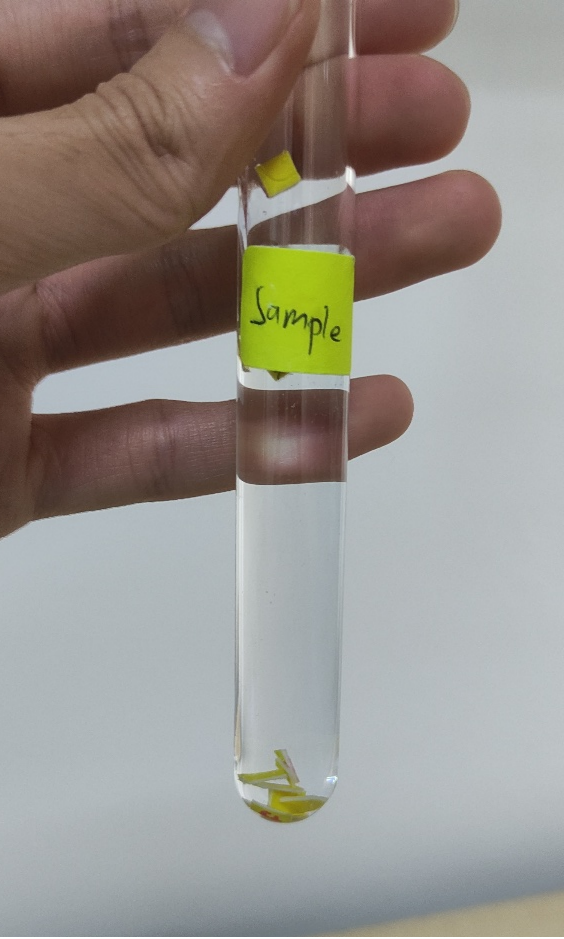

The sample is made into a liquid solution. A UV-Vis spectrophotometer passes a controlled beam of light through the sample solution. By measuring the exact amount of light absorbed by the solution at a specific wavelength, the instrument can precisely determine the Cr6+ concentration.

This method is well-established and approved by regulatory bodies like the U.S. Environmental Protection Agency (USEPA) for its accuracy in water analysis. The application of this technique follows a systematic workflow that ensures accuracy and repeatability.

Results:

Confidence in Safety and Quality

By implementing this UV-Vis spectrophotometry workflow, companies and regulators can achieve several key outcomes:

- Enhanced Safety: The method provides definitive, reliable data, offering confidence that products are safe for consumers and that environmental discharges are free from harmful contamination.

- Assured Regulatory Compliance: Accurate and documented testing ensures that organizations can confidently meet and exceed the requirements of stringent health and safety regulations.

- Brand Protection: A demonstrated commitment to rigorous quality control strengthens a company’s reputation, protecting its brand image and building lasting consumer trust.

- Operational Efficiency: The UV-Vis method is relatively fast and straightforward, delivering rapid results that enable timely decision-making and corrective action if needed.

Conclusion

The diligent monitoring of hexavalent chromium is not just a matter of regulatory obligation; it is a fundamental responsibility for protecting public health, preserving the environment, and upholding product quality. UV-Vis spectrophotometers are a powerful, accessible, and highly reliable tool to meet this critical demand. The adoption of UV-Vis spectrophotometers is essential for any modern industry committed to achieving the highest standards of safety and excellence.

![]()