Conveyor Metal detectors for food are primarily used to safeguard consumers. Metallic contamination in food items during the production process cannot be eliminated, despite all precautions. Metal particles in the product during manufacture or in the raw material can cause harm to consumers. The producing business will face a range of costly recalls and compensation claims, among other negative repercussions. The loss of customer trust caused by contaminated food goods has a wider and more damaging impact than the mere tarnishing of a brand image.

Conveyor Metal detectors offer efficient defense against both ferrous and non-ferrous metals (aluminum, stainless steel, etc.). Every stage of the production process can have a conveyor metal detector installed, and it can be used for a variety of purposes, including the inspection of bread and bakery goods, meat and sausage products, fruit, vegetables, dairy products, spices, sugar, and other items.

Conveyor Metal detectors are used to safeguard machines in addition to protecting consumers. The tiniest metal particles might cause equipment failure. The results are frequently expensive repairs and production halts, which are then followed by drops in sales.

Conveyor Metal Detector Can Avoid Risk

Do you want to reduce the possibility that metallic contaminates may interrupt manufacturing or appear in the finished product? Our conveyor metal detectors provide protection that is precisely suited to your application while reliably detecting all metallic impurities.

Our conveyor metal detector systems use inductive technology to identify all metallic pollutants, whether they are exposed or embedded in the product and made of iron, steel, stainless steel, or non-ferrous metals including aluminum, copper, and brass. A separation unit and a conveyor metal detector work together to completely automate the removal of contaminated goods after sending a signal to the process controls. We meet requirements set by organizations like IFS, BRC, and FSMA with our conveyor metal detectors for the food sector.

Conveyor Metal detectors offer reliable defense against equipment damage, production halts, consumer complaints, and recalls. You may rely on our extensive experience in product inspection and contamination identification, which spans more than 40 years.

How Do Conveyor Metal Detetor Works?

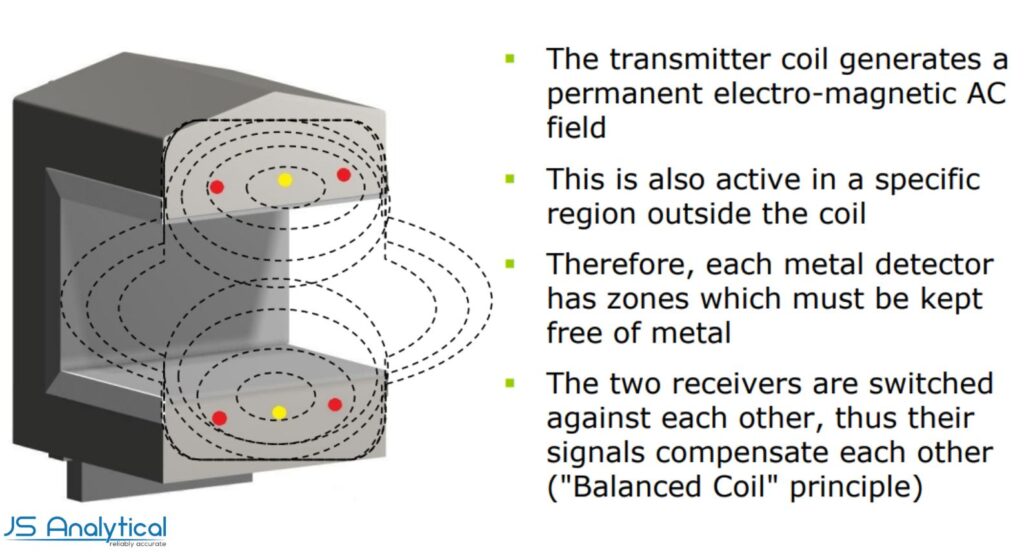

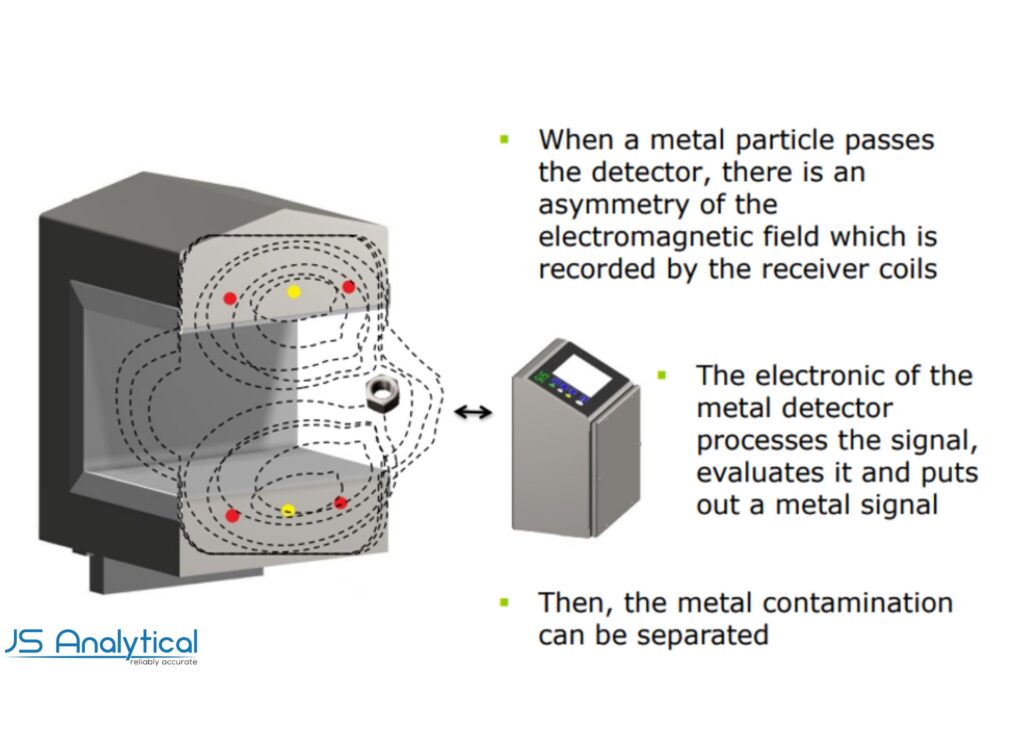

Basically, there are several types of conveyor metal detectors that operate with different detection methods. In the food industry, conveyor metal detectors usually apply the transmitter-receiver method (see graphic).

Such conveyor metal detectors are equipped with a transmitter coil and two receiver coils. The transmitter coil generates a constant electromagnetic field. When a metal particle passes the detector it interferes with the electromagnetic field, causing a signal to be detected by the receiver coils. The electronic unit in the conveyor metal detector analyses this signal, evaluates it and signals a metal contamination. As a rules conveyor metal detectors in the food industry are equipped with automatic reject units that directly separate the contaminated product from the production line.

Benefits of Conveyor Metal Detector

Sesotec is one of the first manufacturers of conveyor metal detectors with artificial intelligence and its products:

- Sesotec is one of the first producers of conveyor metal detectors with artificial intelligence and its products

- Detect contaminants made of magnetic and non-magnetic metal with utmost precision

- Prevent damage to machinery and production stoppage;

- Ensure product quality by mandated standards and certifications.

- Rapid amortization protection against consumer complaints and recalls

Wide Range of Conveyor Metal Detectors with Customization Options

Our whole selection of cutting-edge technology encompasses a variety of goods, modes of transportation, and phases in the manufacturing process. When typical solutions are insufficient, we customize conveyor metal detectors to identify an alternate path. We can rapidly become familiar with your procedures thanks to our many years of conveyor metal detector experience in a range of user-focused sectors, and we can provide solutions that will seamlessly fit into your production line.

We concentrate on making the installation, regular use, and cleaning of our conveyor metal detector systems as quick and simple as possible while designing and developing the conveyor metal detector. Our German-engineered and -produced conveyor metal detectors and systems also have a high degree of mechanical stability and interference resistance.

How Does Conveyor Metal Detector System Works?

Conveyor Metal detector device technology-based induction detection

Every sort of metal is included in the detecting capabilities of our conveyor metal detection systems, rather than only iron or magnetic elements. Our conveyor metal detector uses transmitter/receiver technology based on electromagnetic induction to make this feasible. The conveyor metal detector continuously produces an electromagnetic field while it is in use. A metal object will affect the field if it passes through the detector. The presence of metal is afterward detected by the signal that was sent.

Analyzing digital output from a conveyor metal detector

The control module’s software analyses the recorded signals. Since a product’s inherent conductivity might affect the signal, a conveyor metal detector must be able to accurately discriminate metallic impurities from interference from the environment or the product itself.

To examine signals with reference values that either arrives preset or that are established during ongoing operations, our conveyor metal detector control systems employ advanced algorithms. With this method, they can accurately identify metallic impurities without setting off false alarms. Depending on the setup, the module sends a signal to the process controls, activates the downstream separation unit, alerts the operational crew, and logs the incident if a pollutant is found using the coveyor metal detector.

Conveyor Metal detector separation with little loss

As options for eliminating contaminated items safely, automatically, and with low material loss, our conveyor metal detector offers swivel arms, air-blast nozzles, pushers, rejection flaps, swivel hoppers, and retraction belts. The specific decision is based on the product’s characteristics, the mode of transportation, and other conveyor metal detector criteria.

![]()