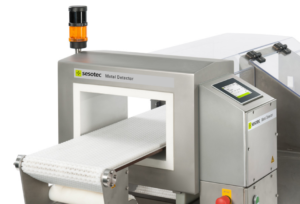

GLS (Metal detector for installation on conveyor belts)

The metal detector GLS with closed detection head and rectangular opening is mainly used to analyse piece goods and bulk material on conveyors or material chutes. It detects all magnetic and non-magnetic metal contaminations (steel, stainless steel, aluminium) – even if enclosed in the product. On detection of metal, a signal device and a separation system can be activated or a signal can be send to process controlling.

The closed design of the detector has the advantage to guarantee high metal sensibility within the detection head. Consequently, this metal detector is mainly used for highly precise detection tasks (e. g. in the food industry). GLS Metal detectors can be combined with numerous separation systems (air blast, pusher, etc.).

The complete systems UNICON+ and VARICON+ – consisting of GLS metal detector, conveyor and partially with separation unit – can easily be integrated into production lines. Due to the optimal coordination of all components, complete systems guarantee highest standards for security and detection precision.