PROTECTOR-MF (Metal separator for extruders, injection moulding and blow moulding machines)

Function

Function chart

Scope of delivery

Options/ accessories

Typical application

Used for

Function

Even small metal particles in molten plastic can cause expensive and time-consuming damage to extruders, injection and blow moulding machinery. As the use of plastic regranulate increases so does the probability of metal contamination, potentially causing blockages in nozzles and filters. However, machine breakdowns, loss of production and delivery delays are not the only consequence; the cost of repairing an extruder spiral or cylinder damaged by just one single larger piece of metal is many times more expensive than the cost of a PROTECTOR-MF system.

In the production of plastics, compounds, composites, etc. the PROTECTOR-MF metal separator ensures product quality.

PROTECTOR-MF metal separators increase machine availability and productivity providing a fast return on investment.

Installation example: Metal separator installed at thematerial infeed. (old version)

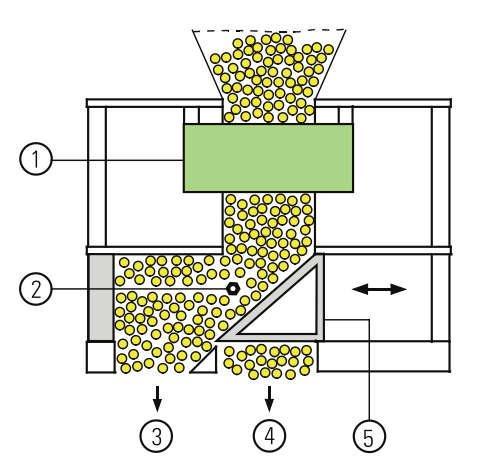

Function chart

- Detection coil

- Metal contaminant

- Reject outlet

- Good material outlet

- Separating slide

Scope of delivery

Metal separator with remote Control Unit PRIMUS+

Options/ accessories

Typical application

Used for