MINIBLEND V

Disc dosing is ideal for translucent and opaque parts as well as for dosing very small quantities.

The demand for excellent mixing quality and consistently accurate dosing is a must when combining additives to the virgin material at the processing machine. The volumetric MINIBLEND V dosing and mixing unit meets and exceeds these requirements. Mounted at the feed throat of the plastics processing machine, the unit requires very little space. Disc dosing is ideal for translucent and opaque parts as well as for dosing very small quantities.

Mixing neck in electro-polished stainless steel The Y shaped mixing necks (single or double) are available in electro-polished stainless steel. They have a smoother surface, which is a benefit particularly for powders and dusty materials.

Quick material changeovers Cleaning and material changeovers are fast and require no tools. The quick-change system, consisting of a removable supply hopper and dosing disc, makes the unit easy to clean and saves you valuable time. The complete dosing module can be used as a colour cassette, allowing you fast colour changes without any previous cleaning.

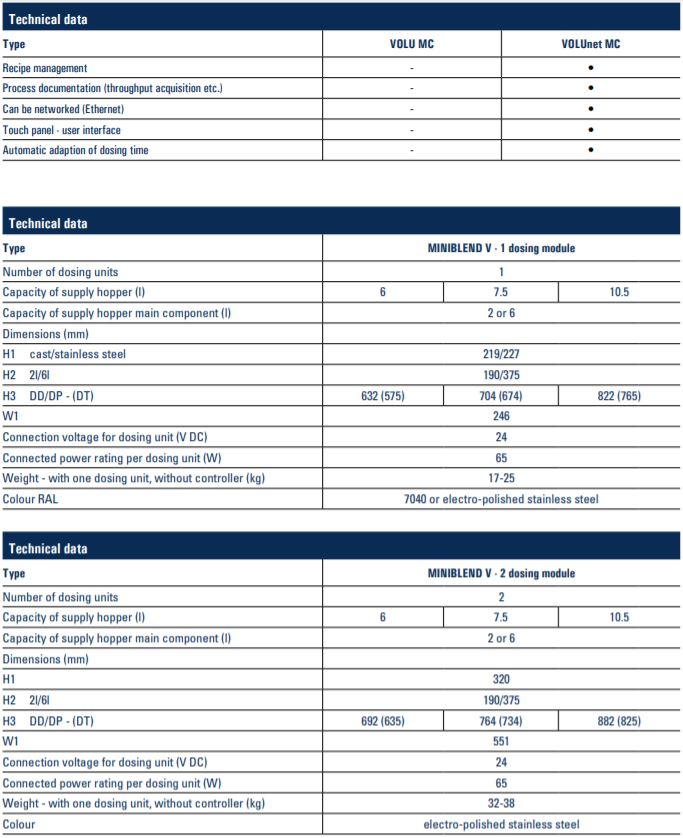

Multiple hopper combinations The MINIBLEND V can be adapted to the needs of your specific application, with three different additive supply hopper volumes (6l/7.5l/10l), in either glass or electro-polished stainless steel, and the option of either manual or hopper loader filling.

Granule cutter When dosing very small throughputs a single granule of material can have a big impact on accuracy. In order to alleviate this problem, all dosing discs are fitted with a cutter which ensures that the dosing chamber is always uniformly filled.

Vertical additive dosing The Y shaped mixing neck allows the main additive to fall vertically into the feed throat of the processing machine, eliminating material hang ¬up or bridging. The main material is kept separate from the additive until they meet just above the throat of the processing machine. They then flow together, resulting in a homogeneous mix with no material separation.

Dosing motor The dosing motor can be removed easily. The motor is brushless and has an integrated motor management which makes it maintenance free. Synchronous dosing Synchronous dosing provides excellent recipe accuracy and reproducibility which can be traced at any time.

Disc dosing The dosing disc with the MINIBLEND V gives you real volume dosing which guarantees very high dosing accuracy – even for very small dosing quantities. The discs are available in eight different sizes (wear¬ resistant design optional).

Dosing of non-free-flowing powders A dosing module equipped with a powder dosing disc, allows you to dose non-free-flowing powders. The compact, modular design gives you the flexibility to meet your changing process requirements. The agitator above the dosing disc constantly keeps material in motion, thus eliminating bridging and maintaining consistent disc fill.