Rapid 8000

Description

Metal Detector for Free-Fall Applications

• Metal detector for the inspection of, fibrous and chunky bulk materials

• Detects magnetic and non-magnetic metal contaminations

• Separation by way of swivel hopper

• Dust-proof reject outlet design include in this metal detector

• Metal detector with Hygienic design for easy cleaning

• This metal detector Complies with IFS and HACCP

• Separation unit and product-contacting metal parts completely made of stainless steel 1.4301 (AISI 304)

• Low mounting height even with large nominal widths guarantees easy integration of the metal detector in existing pipe systems

• Quick and minimum-effort installation due to standard Jacob connection system

• This metal detector has Auto-learn function or manual product compensation (no fixed setting) for improved adaptation to the intrinsic conductivity of the product to be inspected

• Metal detector will Increased interference immunity to electromagnetic pollution and vibration

• Metal detector with Highest scanning sensitivity for all metals

Function of The Metal Detector

The RAPID 8000 metal detector is used for the inspection of bulk materials in free-fall conveyor pipes starting from a nominal width of 200 mm. It detects all magnetic and nonmagnetic metal contaminations (steel, stainless steel, aluminium, …) – even if such contaminations are embedded in the product. Metal contaminations are rejected by means of a swivel hopper. The reject outlet is of dust-proof design during normal operation.

The RAPID 8000 metal detector primarily is used in the food industry in applications with high hygienic demands.

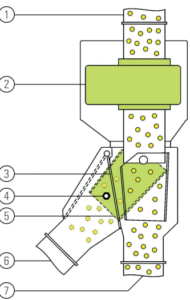

Complete systems

- Inlet pipe

- Detection coil

- Sealing flap

- Metal

- Swivel hopper

- Reject outlet

- Material outlet

Applications of The Metal Detector

• Incoming inspection (product purity and machine protection) of coarse spices with a high dust content, bulk materials with coarse to fine-grained contents, ingredients, raw materials, etc. Prior to the processing machine (e.g. Mill).

• Quality inspection (product purity) of food, sugar, salt, chemical additives (e.g. Ascorbic acid, surfactants), etc. Directly before filling in bigbags and silos.

GENIUS ONE Control Unit Common Features:

• This metal detector has Highest sensitivity for all metals (2-channel technology)

• Digital signal processing and quartz-stable search frequency

• State-of-the-art microprocessor technology with selfmonitoring, auto-balancing, and temperature compensation

• Product compensation with auto-learn function

• This metal detector has Multi-product memory

• Password protection / access protection available in this metal detector

• Special EMC combifilter included in this metal detector for suppressing external interference

Advantages of The Metal Detector:

- Versatility: The metal detector works with various materials like, fibers, and chunks, making it useful for different industries.

- Dual Metal Detection: metal detector can find both magnetic and non-magnetic metals, ensuring a thorough check of materials.

- Efficient Separation: A swivel hopper removes detected contaminants, keeping the production process free from metal impurities.

- Dust-Proof Design: The reject outlet of the metal detector is dust-proof, preventing contamination and maintaining material integrity.

- Hygienic Design: this metal detector is Easy-to-clean design is crucial for cleanliness in industries like food and pharmaceuticals.

- Compliance with Standards: metal detector meets IFS and HACCP standards, ensuring high quality and safety.

- Stainless Steel Construction: Made from durable stainless steel, metal detector resists corrosion in hygiene-sensitive industries.

- Low Mounting Height: Despite its width, metal detector has a low height for easy integration into existing pipe systems.

- Quick and Easy Installation: The Jacob connection system allows fast and easy installation, reducing downtime.

- Adaptive Functionality: Auto-learn or manual compensation adapts to the product’s conductivity, improving accuracy.

- Interference Immunity: metal detector resists electromagnetic pollution and vibration for consistent performance.

- High Sensitivity: metal detector has the highest sensitivity for all metals, ensuring confidence in detecting even tiny contaminants.

Typical fields of application for the metal detector

- Animal feed industry

- Chemical industry

- Food industry