A corporation may make sure that its goods adhere to the industry or company-set standards for quality by using the quality assurance process. The quality assurance process can also be thought of as a business’s procedure for raising the calibre of its output.

Many companies see their Quality assurance process as a commitment to their clients and internal stakeholders that they will produce high-quality products with satisfying user experiences. A comprehensive process for preventing quality defects is a quality assurance process. All phases of a product’s creation, including production, testing, packing, and delivery, will be handling by the Quality assurance team.

The Quality assurance team takes an active approach. Quality assurance teams look for and deal with the causes of quality issues, such as human mistakes or a company employing incorrect materials. The Quality assurance team is actively involved throughout the whole development cycle, ensuring that every part of the product is on track to provide excellent customer service.

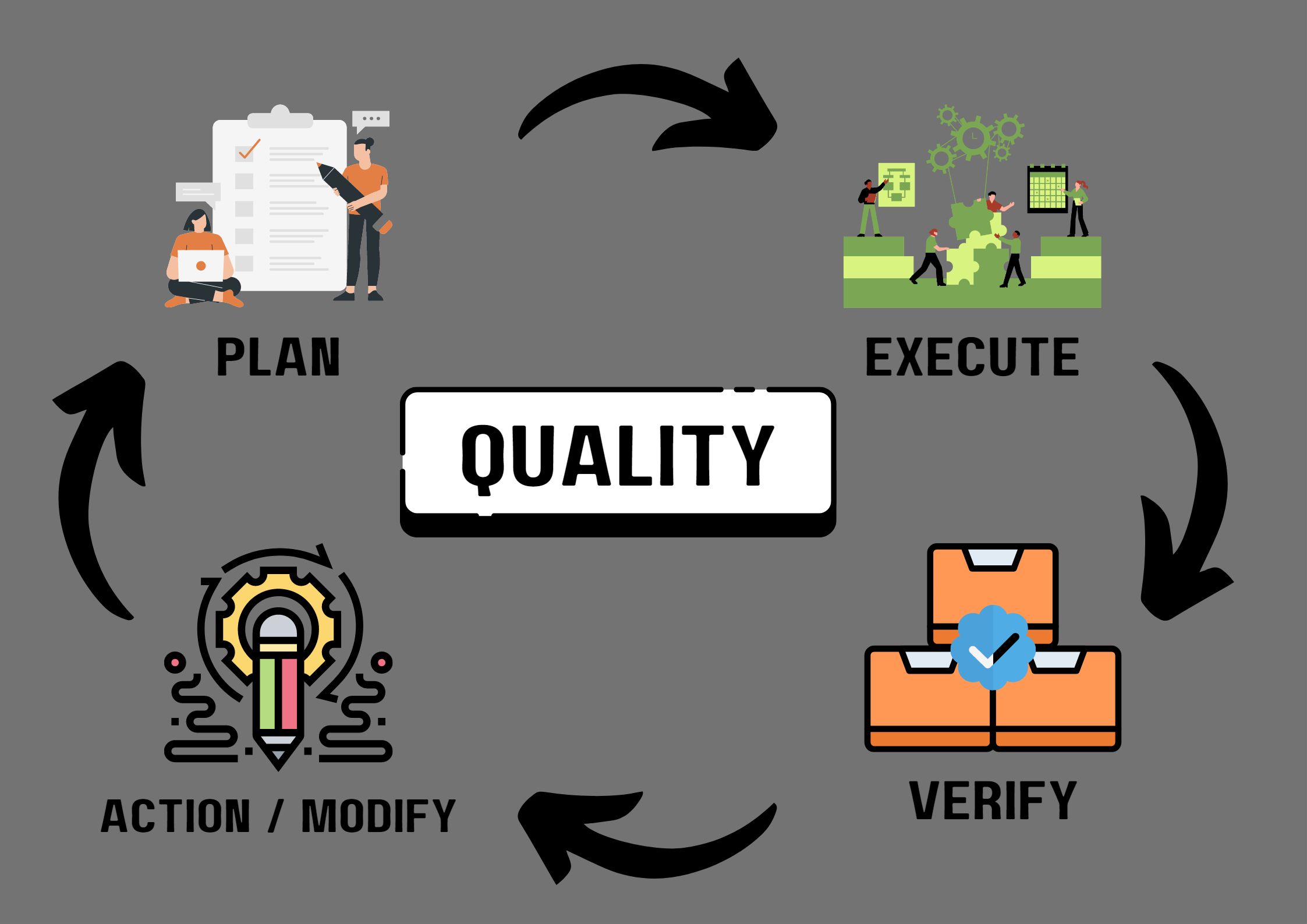

The Quality Assurance Process

- Stage 1: Plan

A quality assurance technician or manager will establish precise goals to manufacture high-quality products during this initial, important stage. Quality assurance will also recommend appropriate techniques to carry out those aims. The company can anticipate any possible issues if they have a good quality assurance team. - Stage 2: Execute

The methods identified in the earlier phase may now be put into practice, as the name indicates. The company executes its quality strategy, which calls for creating policies, hiring employees, and putting quality assurance in place. - Stage 3: Verify

The quality assurance team will be checking and comparing the test findings to what will be predict. This aids in determining if the goods adhere to the necessary requirements. If they succeed, the experts go to the last phase. If not, the quality assurance team return to the initial step to make the required adjustments. - Stage 4: Act and Modify

Based on the outcomes of the previous stage, the organization takes action in this last step to enhance the quality plan. This entails modifying the quality strategy that their quality assurance team has, putting new practices into place, and continuing to keep an eye on the quality outcomes.

Tools of Color Measurement for Quality Assurance

Ci60 Handheld Spectrophotometer

For QC Measurement Standalone

- Entry-level quality control tool perfect for incoming product inspection.

- By employing pass/fail signs on the device, visual evaluation mistakes between samples will be eliminate.

- Simple setup with a high-resolution color screen and programmable menus.

Simple Device Only Solution

In uncontrolled lighting situations, the Ci60 portable spectrophotometer provides an economical alternative to error-prone visual color assessment. Without a computer or software connection, it can take color measurements and do rapid tolerance comparisons thanks to quick compare built within the device.

Simple Installation and Dynamic User Interface

Users may simply adapt and adjust the dynamic user interface to fit their own procedures. The configuration tool for the Ci60 helps users set up the instrument’s basic settings quickly.

Click the link below to know further about the tools :

https://www.jsanalytikal.com/colour-measurement

![]()